The Two Johns

By Carl Doman

From Air Cooled News issue number 6, dated

December 1954

Before the days of powered mowers, fathers universally dedicated the task of lawn mowing to the boys in the family. Of course today the picture is reversed. Dad loves to follow the mower as it is driven about with a direct air-cooled engine. But, to revert back to 1913, my father often stated, "Carl, the lawn is yours to mow; it develops muscles, concentration, etc." So, that was my occupation one beastly hot summer afternoon, when I glanced up as a big black Franklin car drove by on the Hollow Road to Jordan in my home town of Elbridge, New York. Just why I paid special attention to that big car I never knew, but in it was John Wilkinson, the co-founder of the Franklin Automobile Company, and his beloved son, Jack. I had never seen Mr. Wilkinson or Jack before, but I knew them. Why? Because I had seen Mr. Wilkinson's picture many times and had often heard my father remark that Jack Wilkinson was his Dad's constant companion.

That evening I learned that Mr. Wilkinson and Jack had stopped at my father's factory in Elbridge to discuss the Entz non-stall starter which Franklin purchased from the Dyneto Electric Company. Mr. Wilkinson's close friend and neighbor, Carl Amos, had invested $8,000 in my father's company in 1910. He sold Mr. Wilkinson on the ability of my father to engineer and produce just what Franklin needed - an electric starter.

Mr. Wilkinson and Mr. Amos were direct opposites. Mr. Wilkinson was a deep thinker, always deliberate, and a great analyst. Mr. Amos was impulsive, a poor analyst, but a great person with a big heart, who held malice toward no one, Together, these opposites fished, hunted, and argued. My family owes them much,

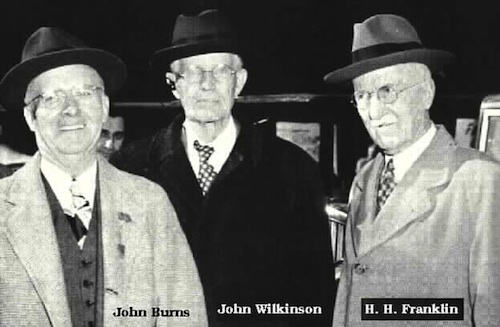

The companionship of Mr. Wilkinson and Jack continued until the son's stay on this earth was so untimely terminated in 1944 just as he had demonstrated to the industrial life of Syracuse that another Wilkinson was ready to carry on the traditions of the world famous engineer and manufacturer, John Wilkinson. But, more about that later. We must introduce the other John of this story John L Burns.

In 1918 my father's concern, the Dyneto Electric Company, developed co-operatively with H. H. Franklin Company a trench lighting plant for the United States Signal Corps. As a boy of eighteen, I was assigned the night shift to observe the generator characteristics, while Ed Marks, a young engineer and later my boss and partner, was assigned the responsibility for the engine operation. Since Dyneto was the prime contractor, it was responsible to the government for meeting specifications.

The unit developed the rated output, but the voltage fluctuated violently due to engine surging. Ed Marks was unable to cope with the erratic operation, so put in a frantic call to his boss, Louis Stellman, Assistant Chief Engineer of Franklin. Louis Stellman fussed and fussed with the governor, but the trouble persisted. Then he called for Ralph Murphy, the Chief Engineer, then only 30 years old. Murphy was an outstanding engineer having been elevated to the chief position after success as Service Manager. Ralph Murphy came to the Dyneto plant where the testing was concentrated. He turned this and turned that, but the "hunting of the governor persisted". Finally, after backing into the exhaust pipe and losing the patch pocket of his new suit, he said to Ed Marks, "Get Johnny Burns, if he can't fix this no one can," To me Johnny Burns was just another person. I had never met him, I concluded that if the "big brains" of Franklin couldn't correct the condition what could a small underling like Burns do. Later I found my observation so erroneous.

In about thirty minutes the receptionist announced "Mr. Burns is here." Ed Marks went to the lobby and escorted the important Mr. Burns to the test area.

Immediately I saw more action, more energy displayed than ever before in my life, John Burns was a slight man of about 36 years, sandy hair, and a barking sharp voice. Immediately I was sold that here was somebody. I was amazed with the respect with which Murphy, Stellman, Marks, yes, and my father paid this man who had been described as "a good mechanic."

To make a long story short, John Burns found the basic trouble in the design of the governor. He proved later very definitely to Mr. Pierce, President of the Pierce Governor Company, Anderson, Indiana, the fault, The governor was redesigned, the generator set accepted by the Signal Corps and production was underway. From the date of the original sketch by my father for Captain Flowers of the Signal Corps to the first test, just twenty-one days elapsed. An outstanding accomplishment for both the Dyneto Company and The Franklin Organization.

This was my first introduction to John Burns, an outstanding engineer, self-trained I will admit, and outstanding man in many areas, and my close personal friend (even though we have many terrific arguments) for thirty-six years. Thus the other member of the two Johns. First let us learn more about John Wilkinson, as his life and accomplishment materially affected that of John Burns.

Mr. Wilkinson was born in Syracuse on February 11, 1868 one of five children of Joshua Forman Wilkinson and grandson of John Wilkinson, first Syracuse Post Master who gave the city its name and who was head of the Syracuse and Utica Railroad nucleus of the present New York Central System.

Educated in Syracuse schools he was graduated in 1889 by Cornell University where he was an outstanding athlete participating in football, baseball, and tennis. Even in 1880 he participated in another sport, bicycle racing, and became one of the country's leading racers. Later in 1895 he designed and patented the "Syracuse quadruplet." This cycle was the fastest in the world establishing a record of 1:45 for a three lap track.

After college he became associated with G.E. Stearns & Company of Syracuse as a machinist. (How different from today. What young graduate would condescend to work as a machinist.) Next, he worked for Henry R. Worthington Pump Company of Brooklyn, then returned to Syracuse to become a draftsman at the Solvay Process Company. After four years at Solvay where he learned the fundamentals of design, so very essential to sound engineering, he joined the Syracuse Cycle Company manufacturers of "the Crimson Rim." There he worked as an engineering draftsman for four additional years. It was while he was employed there that in April, 1896, he married Edith Belden who remained his counselor and guide until his death. (Thanks to Mrs. Wilkinson I am able to include many additional interesting items in this story.)

In 1900 Mr. Wilkinson invented an air compressor self-starter- the first self-starter for an automobile (Kettering claims he invented the starter in 1911). He showed it to a group of friends and out of it came the New York Automobile Company with George H. Bond Sr. As secretary and with Ernest White as Prime Mover. Associated with this endeavor was Fred D. White, Arthur R. Peck, Edward N. Trurp, Alexander Brown, founder of the Brown Lipe Company, and Louis Will of Will & Baumer Candle Company.

Mr. Wilkinson always an exponent of light compact design did not hold much hope for the starter due to its bulk. However, in the development of the starter Mr. Wilkinson built three Pilot Model Air-Cooled Cars. Later this endeavor, fortunately, disintegrated due to Mr. White's death and Mr. H. H. Franklin thereby entered the picture.

Like a great many inventors, John Wilkinson arrived at that point in his life when it required something more than enthusiasm, something more than draftsmen's drawings, to build machines. He needed money.

One day when he was visiting the C. E. Lipe shop, where the Franklin die-casting business was located, he met Mr. H. H. Franklin as he was about to leave and go down-town. Mr. Wilkinson invited Mr. Franklin to take a ride. In that short trip to the center of the city Mr. Franklin saw the unlimited possibilities that there were in the automobile in the future, particularly the air-cooling feature. Following his ride, he had a chat with Mr. Wilkinson and learned considerably more about Mr. Wilkinson's ideas.

Shortly afterward Mr. Franklin interested Mr. A. T. Brown in the automobile idea. Between them it was agreed that Mr. Wilkinson should drop all previous experiments and start anew. At the same time, Messrs. Brown and Franklin, operating under a firm of that name, took over the building and promotion of the Franklin automobile. The initial work of the Company was financed by equal amounts put up by Mr. Brown and Mr. Franklin. So great was Mr. Franklin's faith in the proposition that he borrowed every cent of this money. Later Brown and Franklin were bought out by the H. H. Franklin Manufacturing Company, makers of die castings.

Mr. Wilkinson signed a contract on July 1, 1901, and began the development of the Franklin car. The first drawings were made in the offices of the H. H. Franklin Manufacturing Company, at that time located just a block away from the present Carrier Plant.

Picture, if you can, a little frame building with small offices on the second floor. The original force consisted of six or seven people. In one corner, with a drafting board in front of him, sat John Wilkinson. The bookkeeper, the stenographer and others were at desks and tab1es, here and there. Back in the original machine shop were two mechanics. These two men were building the first car. For two months they had worked shaping up this part and shaping up that, until the day came when they had a complete car. It took those men two months to build it, at a cost of $1100. "Just think of it," said Mr. Wilkinson in 1921, "I don't believe that we could start in to build a new car now for $11,000, let alone $1100.

At the outset, it was determined that the first car should contain a four cylinder motor. This was done to provide smoother riding. Single cylinder cars, at that time, jumped like a jack rabbit as they puffed along. Mr. Wilkinson immediately began to design a four cylinder motor that would eliminate this disagreeable feature and the Franklin became the first car with that type of motor on the market in America.

From the very beginning, John Wilkinson's sole idea was to build a car that would be light in weight and economical. In addition to this, he believed that it should be the acme of simplicity, so that the owner of a Franklin Car would have as little as possible to do with it mechanically. Even the first drawings contained the idea of a self starter. This starter was to be operated by compressed air.

As an engineer, Mr. Wilkinson knew that excess weight was not necessary to hold a car to the road. "In fact," he said, "it is easier to make a heavy car. In order to build a light and efficient car it required more thorough designing and choicer materials. Of course, the finer they were made, the more expensive the making of the car became. But we accomplished what we were aiming to do - namely, to make the car more serviceable. The finer parts had to be carefully adjusted, and that, of course, meant more work and took more time to assemble the car."

As long as Mr. Wilkinson remained in the Franklin picture wood frames and "wood sills" were used. The original machine was made of only the best quality of materials available and was designed scientifically to fit in with the idea of light weight and flexibility.

"Why did you decide on using wood for your sills instead of steel?" Mr. Wilkinson was asked.

"That seemed to me the most natural thing to use," he said, "because wood was the lightest material of great strength that we could find. It has been brought out, as you know, thousands of times, that the wood sill absorbs the shocks that the machine receives while traveling over the roads. It was just another step in making the car as light as possible Any one knows that light weight is essential to efficiency," he ended.

All Franklins through series 19 of 1934 except for series 17 and 18 were equipped with full elliptic springs. This was part of Mr. Wilkinson's original conception as to the best method to insure ease of riding. That the adoption of the full elliptic springs assured easy riding, can be attested by the thousands of enthusiastic, comfort-loving Franklin owners of the past fifty years.

Slowly, but surely, the day came when he felt that he had built a car that was reliable; that would run; that would be of satisfaction to its owner. The third car manufactured under Mr. Wilkinson's direction, was sold to Mr. S. G. Averell of New York City. The first year there were thirteen automobiles manufactured and of these eleven were sold. The next year this number had increased to one hundred and eighty-four, and two years later to seven hundred and twelve.

Little by little the Company progressed. They moved into bigger quarters and each year they saw the necessity for using more space. Ground was broken, buildings went up and still more followed. In all this time, it was John Wilkinson's genius that guided the mechanical development of the Franklin Car. Over every obstacle in years, when the whole nation's business ebbed, and then when it went up and up and money flowed freely and demand far over-reached the supply, he never deviated from the original, fundamental, mechanical principles, except to make improvements that were a positive betterment in the efficiency of the car.

By 1921 when Mr. Wilkinson was honored on the Twentieth Anniversary of the Franklin Car, 70,000 had been shipped. The Franklin was sold in 525 cities in the United States and in twelve foreign countries. From one small building housing sixty-five employees in 1901, in 1921 the Franklin plant covered thirty acres, occupied eighteen large buildings, and employed 3200 loyal workmen. A finished car rolled off the final assembly floor every thirteen minutes; certainly, a great tribute to John Wilkinson and H. H. Franklin.

Even in 1921 at a time when most men were content to sit back and say, "I have finished; my job is complete,' John Wilkinson was found on the job in close touch with all mechanical advancements and improvements not only of the Franklin Car, but also for all automotive industries, aircraft, transportation, etc.

A book could be written solely about Franklin's participation in World War 1, but we will only touch the high points. Of course, backing up Franklin's marvelous Production and Engineering Department was John Wilkinson.

Mr. Wilkinson was selected to co-operate with Cal Vincent of Packard in 1917 to design the Liberty V-12, a 450 Horse Power Aircraft Engine. If I recall correctly, Mr. Wilkinson was assigned the responsibility for the Laboratory System. Other engineers were assigned specific areas, so this marvelous engine was developed in a minimum time and with minimum troubles or "bugs" as they are often designated.

No doubt, Mr. Wilkinson protested the use of water cooling, yet he was the good soldier and went along when direct air-cooling was side tracked temporarily, at least. Later, the engineers at McCook Field at Dayton, the predecessor to Wright Field, did develop a direct air-cooled Liberty V-12 engine. There basic experiments were the basis for later air-cooled cylinder designs used during World War II and today in our military as well as commercial aircraft.

While Mr. Wilkinson was assisting in the development of the V-12 Liberty engine, Franklin's manufacturing boys concentrated on mass production of vital parts for the Rolls Royce engines. In fact, great additions to the factory were erected so that when World War I was terminated, Franklin's facilities for producing automobiles were most complete and as modern as any in the industry.

Mr. Wilkinson's basic engineering philosophy was quite different than that followed by other designers. Mr. Wilkinson often said, "If you design so a part never fails you are carrying around needless material; in a good design a part fails once in a while.”Charles Kettering in another way expressed the same thought when he said, "The more the cast iron the less the brains." In other words, good engineering entailed light weight design using material light in weight, but high in strength.

The rear axle designed by John Wilkinson in 1913 still stands as an outstanding accomplishment. It incorporated a simple cast gear housing into which was pressed and riveted tubes on the end of which were mounted the brake assemblies. The ring gear and pinion were carried on ball bearings and were always kept in proper relation to each other. Axle gear noise in a Franklin was a rarity. In 1954 it is a major problem for automobile makers. Also, in 1954 the basic design of the Franklin axle is followed by Lincoln, Mercury, Nash, Studebaker, and others.

Mr. Wilkinson always resisted increases in weight. His rear axle pound per pound was the lightest in the industry. Many in the Franklin organization suggested a malleable iron center housing instead of aluminum. They argued that it should be stronger and cost less. Mr. Wilkinson disagreed as far as strength was concerned. Cost was secondary. He decided to demonstrate dramatically the rigid features of his design. Accompanied by Ralph Murphy, Ed Marks, Harry Digney, General Manager, of Oberdorfer Aluminum & Brass Foundry, makers of Franklin castings, he proceeded to the roof over the sixth floor of the Franklin plant with a regular aluminum axle center housing, a duplicate housing in famous Oberdorfer zinc alloy and a cast iron housing. He then threw the castings one after another over the side of the building down onto the concrete court. Next, the group darted down the stairs to the ground floor - elevators were just too slow. Jubilantly, Mr. Wilkinson pointed out the "projectiles." The cast iron housing and the regular aluminum housing were cracked in many pieces. The Oberdorfer "V" alloy was intact, not a crack, in perfect shape. Franklin specified the 'V" alloy for immediate production. Cast iron housings were forgotten for several years until Mr. Wilkinson no longer dominated the engineering activities of the company.

The average engineer invariably designs a part such as an exhaust manifold or an intake manifold to be made in cast iron, a heavy, low strength material. Mr. Wilkinson was the average engineer? Never. Mr. Wilkinson designed his manifolds to be fabricated from light weight thin wall steel tubing, just like aircraft engines use. He longed for the day when he could use aluminum tubing, but that day never arrived for him. Today, aluminum intake manifolds are universally used in aircraft. Mr. Wilkinson's vision was unequaled.

Contrary to the policies of most automotive companies producing cars today, Mr. Wilkinson designed so that the majority of the parts were built in the Franklin Plant. It designed and manufactured the complete engine including the carburetor, the bearings, connecting rod forgings, valve springs, pistons, etc. It also manufactured transmissions, front and rear axles, steering gears, stampings, bodies, instrument panels, etc. Possibly, it could be argued that a parts specialist could do a better job, yet what part specialist ever came near designing with the finesse of Mr. Wilkinson and his associates.

I have mentioned often Mr. Wilkinson's designs. Actually, no one engineer is responsible for an automobile. I actually mean that Mr. Wilkinson so inspired his engineering associates in his philosophy of design that the entire organization operated as one. In short we all believed that Mr. Wilkinson's basic theories were correct. History has proven that he was correct, otherwise, Franklin would never have been first so many times. Just look at the following list of firsts:

- First 4-cylinder engine (1902). Original model built in 1898.

- First in scientific light weight and flexible construction (1902).

- Fundamental features, such as light unsprung weight, full elliptic springs and air-cooling appeared in first car marketed.

- First in valve-in-head cylinder (1902). This construction used from the first Franklin built.

- First in throttle control (1902).

- First float-feed carburetor (1902). As simple as the carburetor throttle control and float-feed now appear, they were never used until Franklin showed the way.

- First 6-cylinder engine (1905). This engine was exhibited at the 1906 New York Automobile Show.

- First to employ drive through springs (1906).

- First to use transmission service brake (1906).

- First to adopt automatic spark advance (1907).

- First to use individual re-circulating pressure feed oiling system for engine (1912).

- First to use exhaust jacket for heating intake gases (1913).

- First to use an electric carburetor primer to facilitate cold weather starting (1917).

- First to use case-hardened crankshaft in regular production (1921).

- First to use centrifugal air-cleaner for carburetor (1922).

- First to use Duralumin connecting rods in regular production (1922).

- First to employ narrow steel front body pillar construction (1925).

- Pioneered aluminum pistons (1915).

- Pioneered closed bodies. First production sedan (1913).

Another very important first was his assistance in founding the Society of Automotive Engineers. In 1947 he was honored for life membership at a special meeting in Syracuse. I can well recall that evening. Mr. Wilkinson was so calm. The honor, great to the audience, meant little to him. He was so modest and great this night as always.

As we look back from 1954 to 1901, we see more evidence of Mr. Wilkinson's great contributions. Here today overhead valve engines are claimed to be a recent innovation, yet Franklin cars always used them. To handle the high compression ratios of today seven bearing crankshafts in six cylinder engines or five bearing in V-8 are needed. John Wilkinson always used the multibearing design.

In 1920 the Franklin directors concluded that the fundamental features of the Franklin Car should be incorporated in a low price vehicle. One that would sell for $1,000. So, additional stock was sold, acreage was purchased on Thompson Road just opposite the Oberdorfer Foundry, and a separate organization was set up in a building on South Salina Street to design, develop, and prepare for production of this new small car.

For Engineering James L. Yarian was drafted from Franklin's truck activity. For Production an old master was chosen, Joseph Baboock. There they then surrounded themselves with outstanding associates.

Mr. Wilkinson was enthused as the cars took form. He, like Henry Ford, believed in cars for the masses.

Eventually the cars were assembled then road tested. Everyone was enthusiastic. The performance was very satisfactory and the riding quality outstanding. I well recall the car as I had decided to join the Small Car Division directly after graduating from the University of Michigan. Then as suddenly as the project was started, it was stopped. Why? No one seemed to have the answer However, as I look back on the situation through the eyes of a mature person rather than through the eyes of a twenty-two year old, I believe it was simply the lack of capital. Large production would have required high sums for working capital. In 1954 as I regretfully look back on the Small Car project I can see the turning in the road for Franklin. Had it been able to continue with this car I am convinced that "Franklin" would be another Ford, or another Chevrolet, or another Chrysler in sales volume and industrial strength.

The termination of the Small Car Division meant that I was out of a job for a few hours. I immediately hired out as a student engineer under Ed Marks at the main Franklin Plant. Thus, was re-established an association and friendship which still is as strong as Gibraltar.

It fascinates me how Franklin could pioneer so many engineering advancements with minimum expenditures. I can only say that in Franklin's Engineering Department there were no specialists. Every engineer was broad. He could design, he could develop, he could compute costs, he could design production fixtures, and he always produced a design that was practical. Today the direct opposite is used. It is a day of specialists; only the big division saves the day. Millions of cars produced offset expensive designs.

Mr. Wilkinson's designs were never complicated. Take the unit power plant produced first in 1921. Here for the first time the transmission was mounted directly on the engine. Today as I look at that 199 cubic inch engine I remark what a simple low cost design. Why can't the basic features be reproduced in 1954. Its inherent low costs would startle the industry.

In 1954 engineers make great claims for new automobile engine developments. They infer that large base short stroke engines are new discoveries. Yes, amusing when one realizes that John Wilkinson promised this relationship in his first air-cooled engines.

In the Society of Automotive Engineers transactions Volume I, 1913, Mr. Wilkinson presented a lengthy discussion with basic calculations on the effect of the Relation of Stroke and Bore in Auto Engines. Wilkinson designed Franklin engines were truly designed, not developed by cut and try as were so many of the early power plants. Fortunately, I have the complete transactions of the Society since its incorporation in 1909. In many of these volumes Mr. Wilkinson's contributions stand out as classics. He discussed with authority not only engines, but steering, transmissions, riding, etc. We could spend hours reviewing his most interesting observations. A great engineer, Mr. Wilkinson, a great man acknowledged as such by this great engineering society many, many times during his career.

While Mr. Wilkinson after 1921 assumed less and less production responsibility, he had more time for original thinking. He experimented with new types of suspension, sleeve valve engines, rotary valve engines. In fact, he was way ahead of the rest of us, yet he was always available for consultation and advice. Young engineers were always welcome for counsel. Mr. Wilkinson always welcomed new ideas and he expected young engineers to have them.

In 1924 Ed Marks came to me and said, "Carl, you have been working alone after the big layoff early this year. You are going to have a helper, Jack Wilkinson." This news pleased me immensely as I had looked up to Jack ever since I had seen him in 1913 riding down Jordan Road with his father.

Jack was a willing helper. He learned to use hand tools very readily. He operated the electric dynamometers, observed our test engines like a veteran. Mr. Wilkinson would occasionally drop by with an excuse to chat with Jack. Truthfully he wanted to see with his own eyes the progress of his son. I am sure he was satisfied and proud. He often thanked me when Jack wasn't around.

The summer was just too short. Jack returned to school and the Engine Laboratory or the "dog house" as we called it, returned to my sole custody. I will always remember Jack as a fine young man with great possibilities.

Mr. Wilkinson decided to leave Franklin in 1924 for reasons never explained. His departure was a great shock to all who knew him. Immediately he began development work for Dodge Brothers then headed by his old friend Fred Haynes.

Surprising as it seems, his first effort was the Dodge water cooled "Victory Six."

Some argued that he specified water cooling in the Dodge as a spite to Franklin. Those men such as John Burns, Ed Marks, Ralph Murphy, who knew him intimately said, "Never." He designed a water cooled engine simply because Dodge Brothers demanded it. Mr. Wilkinson was assigned a definite task. He was paid for it and he did the job successfully.

Mr. Wilkinson in his retirement kept active and his mind couldn't be content unless it was active. Just to illustrate his mental processes, even in 1950 he was fascinated by jet engine development. I am quoting from a letter written me by his son-in-law Alden Sherry, a member, incidentally, of Captain Eddie Rickenbacker's squadron and today a very close friend of Mr. Rickenbacker.

"I was a fighter pilot in France in 1917-18 and in 1941 was asked to come back in the Air Force. In '42 - '43 I was stationed in England and North Africa (Sahara Desert) and in '44 in Italy (a tough campaign). In between I went to India, China, and Russia with Eddie Rickenbacker on a mission for Secretary Stimson.

"When I got home my father-in-law was full of questions. I went back to the Le Rhone engines that powered our transports in '17-'18 and wound up with the first jet our pilots had ever seen. It was in Sicily and I think the fall of 1943. We know the Italians had developed a jet and we came to the conclusion this one had been hidden out in the Sicilian wilds.

"Of course, he wanted to know all about it, but as we were still flying radial engines, I was of no help.

"To make a long story short, about 1950 the National Guard Squadron here received some jet aircraft. In the meantime, I wrote to the top man on aircraft per G.M. in Detroit. (I forgot his name). He had worked with J.W. on the Liberty in Detroit in 1917-1918. I asked him if he would send J.W. all the jet stuff he could part with. Well, the stuff he sent him kept him happy for a year. Then one day he asked me to take him out to Hancock Field. When he got there he said he wanted to see a jet. We found one on which a young lieutenant was working.

"He invited us to climb up and look it over. For about fifteen minutes J.W. inspected it, then he started asking question of the officer. Well, at the end of the next fifteen minutes the poor guy was in a state of exhaustion.

"He took me aside and quietly asked, "Who in hell is this old bird?" I gave him a quick history. "Well, how did he become so familiar with jets? Don't tell me he had one in a Franklin."

"No," I said, "This is the first one he has ever seen." He looked at me a long time. Then as he started to walk away, he kept saying, "I can't believe it. I can't."

.Mr. Wilkinson's life was most complete. He was fortunate for fifty-five years to have a most wonderful wife. She still lives in Syracuse at 1065 James Street and, frankly, has wanted for many months to review this story of her husband so interlocked with that of John Burns. Mr. and Mrs. Wilkinson were blessed with three fine children, Jack Wilkinson, Helen Wilkinson Blagbrough, and Anne Wilkinson Sherry. Today only Anne survives. However, Mrs. Wilkinson today is content. She has her seven grandsons, four granddaughters, and twelve great-grandchildren. All listen most willingly to grandmother's stories of grandfather Wilkinson's accomplishments. Can you blame them for being proud of a grandparent who has contributed so much to automotive progress? I know of no one who has contributed more.